By Ryan Arcadio

From Peranakan to Indian, Singapore is home to a bewildering array of cuisines. Behind the scenes of the glitzy Michelin-starred restaurants and open-air kopitiams is a thriving food manufacturing industry supplying safe and high-quality products for that uniquely Singaporean taste. In 2018, the food manufacturing industry employed about 50,500 employees—contributing over S$10.7 billion in output, with about 60 percent exported globally.

Like others across the world, however, many food manufacturing operations—big and small alike—were forced to temporarily shut their doors and go digital during the pandemic’s peak last year. Though Singapore has since settled into the new normal, the importance of digitalisation remains.

To help SMEs go digital, the Infocomm Media Development Authority (IMDA) and Enterprise Singapore (ESG) has rolled out the Food Manufacturing Industry Digital Plan (IDP). Set to benefit around 1,000 food manufacturers producing everything from snacks to spices, the IDP includes a three-stage roadmap that outlines the digital solutions SMEs can utilise as they grow.

The first stage presents basic digital solutions for streamlining operations and automating labour-intensive tasks. Meanwhile, the second stage offers digital solutions to attract new customers and establish a connected digital presence. For the final stage, the roadmap encourages the use of frontier technologies like artificial intelligence and augmented reality to better train workers and predict patterns in their production line. In this feature, discover how three SMEs in Singapore embraced digitalisation by following the Food Manufacturing IDP.

Making operations batter and more efficient

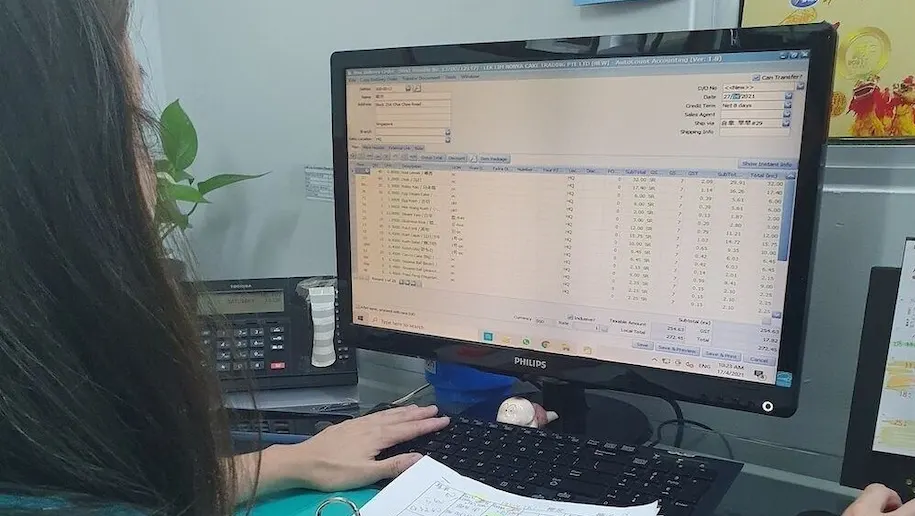

Founded in the 1960s, Lek Lim Nonya Cake Trading prides themselves on their traditional Nonya kuehs. As the business grew and Lek Lim supplied more shops through the years, the company had to spend increasingly more time creating paper invoices. Recognising this bottleneck, they quickly adopted an accounting software to support the growing business.

I used to spend 15 days per month to generate and send paper invoices. By using the accounting software, I no longer have to do those manually as I can retrieve any invoice from the system easily.

Ms Liew Mui Kiun

Customer Service Executive, Lek Lim Nyonya Cake Trading

Incredibly, their new accounting software could easily be integrated with an e-commerce platform that has helped boost kueh sales with minimal paperwork. While Lek Lim’s managing director, Mr Gavan Sing, admits that embracing digital solutions was hard at first, he believes that it is crucial for the company’s growth.

“The first step is always the hardest, especially for a small company like us, but we know going digital is crucial for growth in the long run,” he shared. “We are [now] embarking on a new project to use data analytics to uncover productivity bottlenecks in our manufacturing processes. There are many opportunities awaiting, but we need to go digital to grab them.”

Finding the sweet spot of digitalisation

With five retail outlets across the country, Baker’s Brew is one of the fastest-growing companies in Singapore today. Specialising in artisanal confectionery products and even offering baking classes, the company is looking to expand to 20 outlets in the next three years.

Having been established in 2015, it’s no surprise that Baker’s Brew found its digital footing right away. Still, when their physical shops had to close due to strict safe management measures implemented in April 2020, the bakery had to quickly pivot and make its operations digital-first. Using their website and existing e-commerce channels to receive and fulfil orders, Baker’s Brew managed to continue their operations without much lag time, compared to other establishments without an online presence. Since then, the company has explored other digital solutions.

We have tapped on the Productivity Solutions Grant to adopt a cloud-based point-of-sale system that allows us to check sales data and make decisions on production rate in real-time.

Mr Beh Huat Jin

Managing Director, Baker’s Brew

Building upon their firm digital foundation, the company now plans to integrate more digital solutions in the future, such as an app-based fleet management system and even a customer relationship management loyalty programme to reward loyal patrons with a sweet treat.

Finding the right mix

Whether you prefer Spanish Iberico or a hearty German sausage, Tiong Lian Food Pte Ltd has it for you. As Singapore’s leading importer and distributor of chilled pork products, Tiong Lian offers a plethora of chilled, frozen, marinated pork, and even sausages and ham.

“The meat sub-sector in Singapore is still largely reliant on manual processing,” explained Mr Kelvin Teo, an assistant operations manager at Tiong Lian. “As our business grows, manual work becomes harder to keep up.”

In 2018, the company finally decided to take the digital leap during their planned factory relocation. Sensing an opportunity to refresh their production line, Tiong Lian integrated automated systems for storage and retrieval, as well as warehouse management, into their operations—to great success.

For instance, operations supervisors previously had to oversee the manual counting and reconciliation of inventory after every shift. With Tiong Lian’s new warehouse management system, inventory data is automatically updated onto the platform. In addition to enhancing production operations, Tiong Lian also developed a B2B e-commerce mobile application to digitalise order processing for customers and sales personnel, helping improve business processes efficiency by 20 percent.

Thanks to Tiong Lian’s efforts to go digital, quality controller Ms Tee Chai Xiu has seen her job scope increase in relevance. “My job now includes making production decisions using data reports which were not available previously. The rewards in terms of productivity and job satisfaction are tremendous,” she said.

While digital transformation may be intimidating, the IDP offers easy-to-follow ways to help SMEs in Singapore go digital and take those first digital steps. Find out more about the IDP’s recipe for digital success here!

.webp)